Posted on 21st Dec 2022

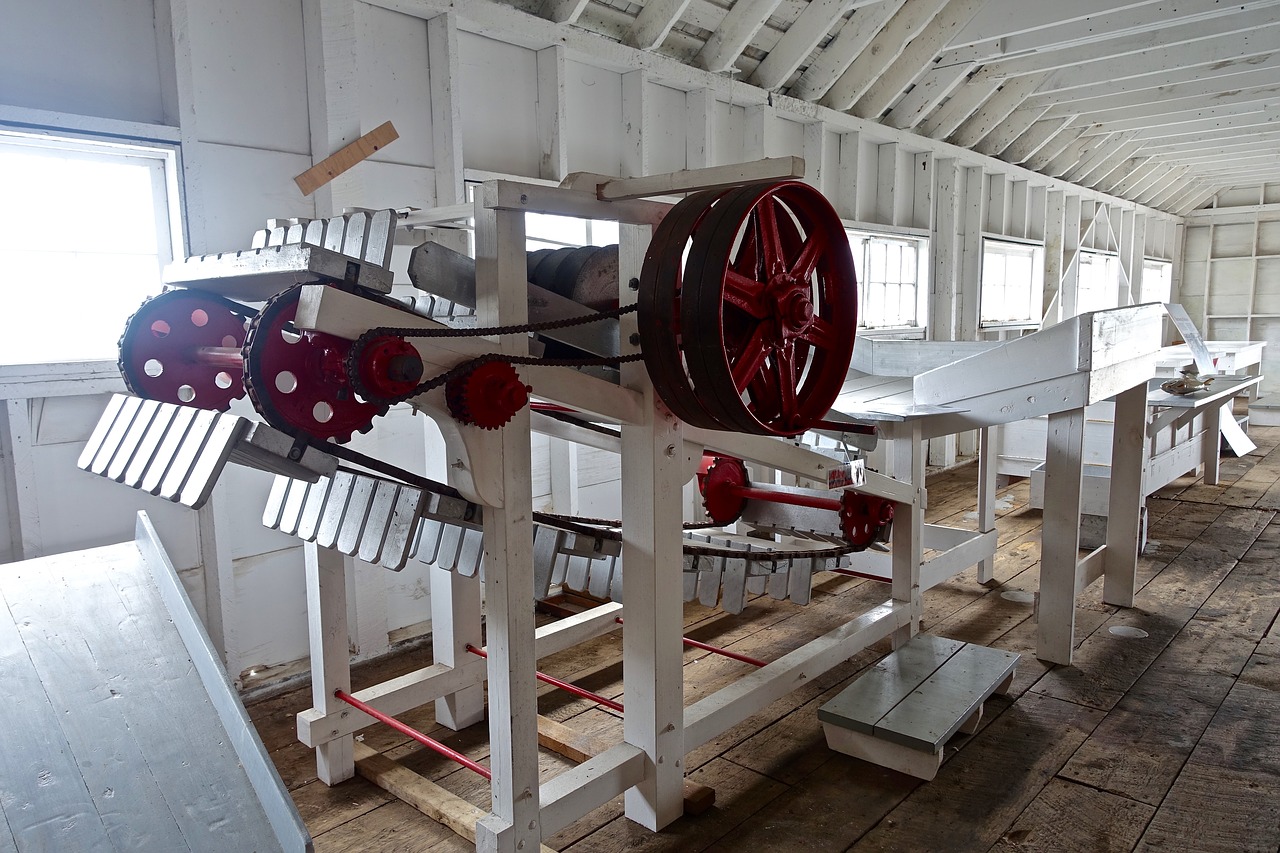

Automation systems installed in industry can help a lot because you can perform certain operations by using a robotic or control system. There are various processes that can be used in computers and software to perform such work. Industrial automation has marked as a revolution in the manufacturing industry and the process. There are different types of industrial automation systems available here, you can find a few examples:

You can use sensors in the high traffic area of your industry to monitor the activity of the people. Apart from that, you can find automatic food and beverage packaging system the food industry. It can reduce human contamination and labour to a large extent. Even, 3D printing, and numerical control machines are very common to us, and we can easily use such an automatic system to keep our production faster.

Benefits of an industrial automation system:

You can reduce the cost of the operation by using an industrial operating system. For example, you need to recruit more than a thousand people in your production line, and you need to pay their wages and other benefits. You can simply use some robots to do the same work in less time and you can recruit a few supervisors to monitor the whole process. Initially, you need to invest a lot of money, but it will reduce your production cost in the future. Apart from that, human error is very common, and you need to suffer from the wastage of raw materials and products caused by your operators.

In the case of industrial automation, you can reduce the cost because robots cannot make an error in their operation.

Robotic processes or industrial automation systems mainly mimic human actions, and you can use such automatic resources to increase the productivity of your business. You can also configure an automatic system to complete your administrative work. With an industrial automation system, you can use robotic applications to keep your workspace clean, and they can even handle your high-pressure machinery without any harm. If you use a manual process for manufacturing your products, then there will be a chance of human error. Even, manual handling and packaging of your products can damage your products and you need to bear the loss.

For production growth and reducing wastes, the automatic use of machinery can help in several ways. On-time shutting of the machine operation and restarting of productions are the main features. an If you are dealing with heavy materials, then you need to maintain the best safety protocols. It is an application for hazardous materials too. In this case, you can use an industrial automation system to prevent damages and the risk of an accident.

Apart from that, you can maintain the temperature of your workspace by using some robotic sensors. Even, theautomation system can also save your power consumption cost, and you can use an automation system to connect your electrical devices. You can control all your devices and appliances from a control panel.

There are some machine learning apps available that can be used to build a self-learning control quality system. Skilled workers are specifically trained to use such a system to maintain the best standard. An automation system can consistently deliver the same production level and you can reduce the downtime caused by the human interface.

To know more about industrial automation, you can search such tools online and you can choose the best solutions for your industry. You can customize such apps and software-operated machines or robotic applications as per your needs.