Posted on 21st Dec 2022

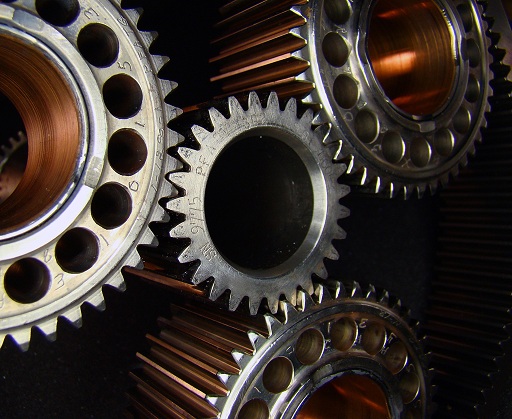

Geared motors are a combination of an electric motor and a gearbox, often used for high torque and minimum speed applications. It is simple and cost-effective solution to get best energy efficiency.

The gearbox permit to raise torque while decreasing the speed of the main mover output shafts. In other terms, geared motors operate like a speed and torque converter. Particularly, geared motors utilize the mechanical benefit by passing on motion from the input shaft to the output.

CM Industry Supply Automation shares some common types of gearmotors:

There are various classifications of gearmotors. The first is made based on the power of the gearbox and differentiating three major models such as angular gearbox, parallel shaft gearboxes, and planetary gearboxes.

However, it even depends on the motor type, with the major difference being between AC or DC motor. Actually, gearmotors can utilize AC or DC power, though nowadays the most usual ones have a three-phase asynchronous motor or a permanent magnet synchronous servomotor. This differentiation can affect several performance factors such as cost, reliability, and speed control complexity.

What are some industrial applications for gearmotors?

Lenze geared motors are often used in applications, which need a high output torque and a minor output shaft rotation speed. In addition, they are a mostly perfect solution where space and power are restricted thanks to their dense design and modularity.

Among the potential applications of gearmotors, we have discovered many systems and devices in various sectors such as:

How to choose the right gearmotor

Review the function necessities for the gear motor, explicitly:

From mounting orientation, dimensions and other general requirements.

Voltage, frequency, power source, maximum current, etc.

Noise level, weight, dimensions, and other gear motor specifications.

Speed, power, torque and other gear motor performance.

Ingress protection degree, application, and ambient temperature.

Choose the right motor according to the application requirements.

Industrial Gearmotors, motors, and controls drive industrial automation

Whether you are looking for the maintenance-free performance of variable-speed AC 3-phase, the high initial torque of gearmotor, or a blend of both, CM Industry Supply Automation have the perfect drive solution for your conveyor application or industrial automation.

Learn more from our industrial automation blog!