Posted on 21st Dec 2022

With servomotors normally used in precision manufacturing, its long downtime cost you high. If a servomotor is not working properly, it is important to perform a quick repair. A fast come back to service must be with an assurance of a highly-skilled repair that offers lasting, high-performance movement control.

Sophie Williams, Marketing Manager at CM Industry Supply Automation talks about the key requirements of servo motor repair.

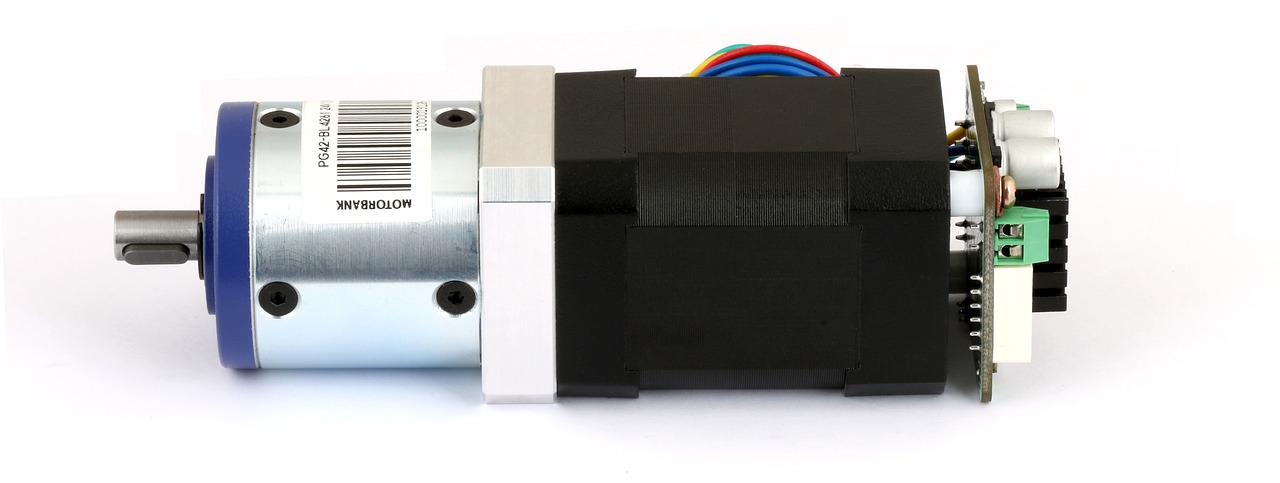

Servomotors are an important component for manufacturing processes starting from printing and packaging to electronic device production. Its downtime costs you high as production rate decreases, project completion deadline misses and reputation gets damaged too. For these concerns, if a servomotor develops a fault, it must be repaired as quickly as possible. A servo motor is capable to offer exact precision at high speed, so any repair must offer it similar performance to a new one.

CM Industry Supply Automation offers 24/7 365 days in-house repair service for servo motors in India and Australia. Our servo motor repair service aims to get a client back up and running within a short time frame.

When the servomotor comes to our workshop, our first job is to diagnose the problem. From the point the fault is determined, the repairing process resume and we try to complete the motor repair within 24 hours. Communication with the client is crucial and they are updated at every step of the repairing process.

Usually, servo motor faults occur due to bearing failure or encoders and brake inaccuracy. In many conditions, these issues occur due to wear and repeated use. Used for accurate position control and maximum-pace acceleration, a servo motor is essentially more complex to repair as compared to an induction motor.

In diagnosing phase, basic electrical tests are performed along with insulation resistance tests. Also, we do alignment tests, analysis of the internal brake, and significantly, encoder count. After that servo motor is stripped and cleaned with the repair or replacement of the encoder as per the requirement, and the brake refurbished.

To achieve the essential precision, a balance test is performed on the rotor to eliminate vibration for better performance and reliability. As normal, the bearings are even checked and replaced as required, as well as the electronic measurement of the housing that can be machined to the correct size to ensure an exact fit for precision and motor long life.

Even the stator is overhauled by removing corrosion on the windings. If essential, rewinds can also be performed in-house, often require eight and 10 hours to complete. Core loss testing even happens in-house to confirm the performance of rewound motors, and expert also checks noise and vibrations.

The servomotor can even be resprayed onsite. Next, with the encoder alignment set, a load test is carried out together with a servo drive, as well as testing the brake. When our experts announce that the servomotor is set to re-enter service, it is despatched to the client's site, prepared for reinstallation.

Our workshop is completely equipped and configured to repair all types and brands of servomotor. If the servo motor is beyond repair, CM Industry Supply Automation offers new servo motors of major brands such as Lenze, KEB, Siemens, Rockwell, Allen-Bradley, ABB, Control Techniques, Mitsubishi, and more at affordable prices.

Call us now for Servo Motor - Servo Motor Repair Services at +918888851242 or +61432112288.