Posted on 21st Dec 2022

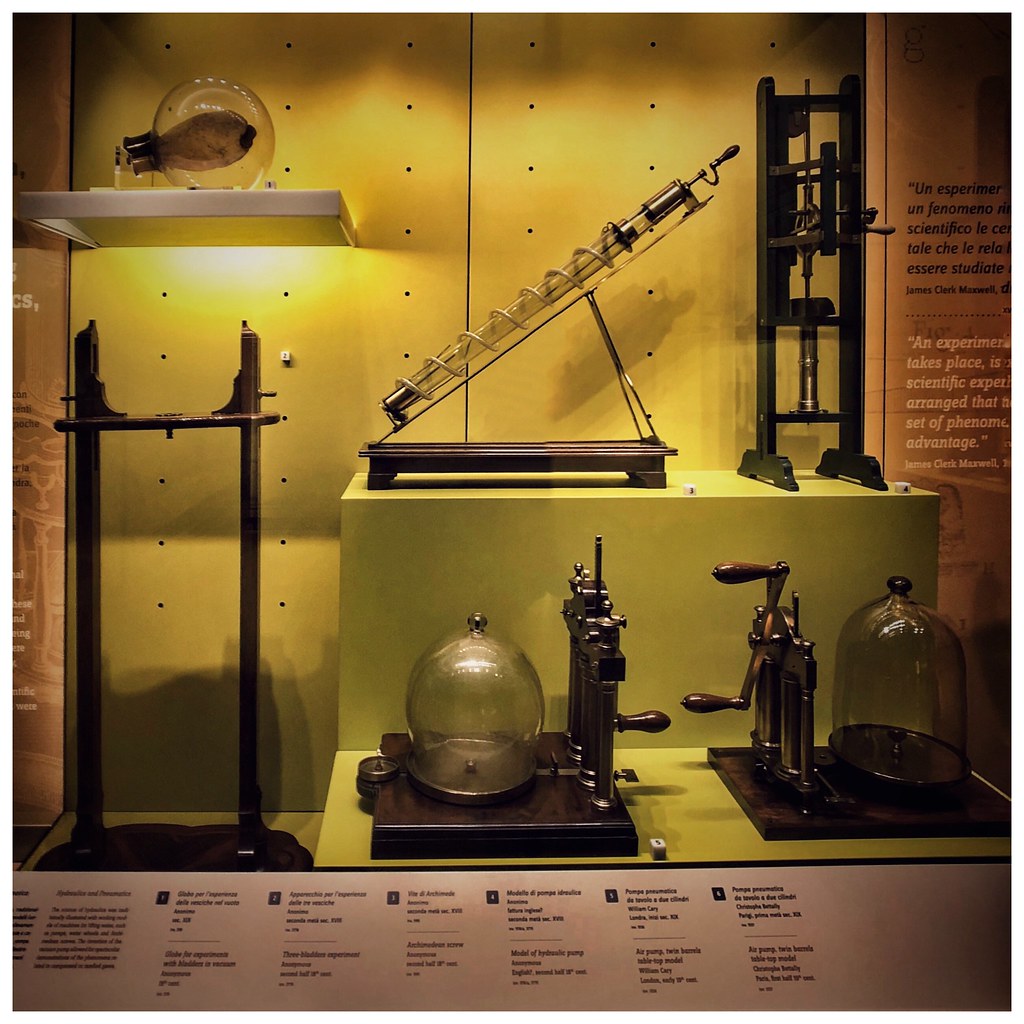

Hydraulic and pneumatic systems are utilized for various procedures. Valves controlled both these systems by directing the fluid to the actuator, which is the place where the fluid power is transformed into mechanical power.

CM Industry Supply Automation shows some deep insights into the differences between hydraulics and pneumatics systems:

Hydraulics: The Supremacy of Uncompressible Fluids

Mineral oil, water, synthetic fluid, or ethylene glycol are all these liquid forms, which are the heart of hydraulics. These liquids are uncompressible which enables workers to adapt the flow of fluid to manage the system. Hydraulics is usually found in heavy-duty machines or devices such as cars, industrial lift systems, etc.

A classic hydraulic actuator will work at 4,000 psi pressure. It can even hold the force or torque constant with no extra fluid. The incompressibility of fluid is the main factor. Even, the power loss is minimal, because the distance between actuator and hydraulic pumps increases.

Pneumatics: The Flexibility of Compressed Gas or Air

Pneumatics relies on gas or air to spread power. As this gas is compressible, it offers similar functionality to hydraulics. Pneumatic systems go with applications wherein the overall procedures are faster, and where not great force or accuracy is required. Pneumatics is often utilized in medical equipment, high-powered drills, and factory automation systems.

The initial expenditure of designing a pneumatic system is minor. Some systems depend only on air. Material charges are low as well. However, the long-term price can be more expensive as compared to hydraulics, as keeping atmospheric air at operating pressure needs huge power.

A great benefit of pneumatics utilizing air over hydraulics for low-pressure applications is that the air can be worn out straight away from the actuator that means there is only a requirement for a supply line.

When do we utilize hydraulics or pneumatics?

Hydraulic devices applications are good for when there is a need for higher force and heavy lifting. Moreover, pneumatics is utilized for mechanical and lighter engineering requirements.

Why hydraulic and pneumatic system maintenance is crucial?

The most crucial reason is safety. Pressurized hydraulic fluid, which suddenly breaks out presents the danger of unstable velocity. One more hydraulic safety concerns the damage that faults can cause with unpredicted movement by pointed, heavy equipment, injuring those, which are close. Proper maintenance can assure safety and reduce downtime.

Remember that fluid power hydraulic and pneumatic systems require low maintenance. Pneumatic safety measures include making sure hoses are free from injury. Aged or fraying hoses usually leak air that becomes the reason for the malfunction of equipment. In return, it can cause severe harm to users.

Buy Hydraulic and Pneumatic System Today

We hope that this article helped you to understand the difference between hydraulic systems and pneumatic counterparts. CM Industry Supply Automation is one of the biggest hydraulic and pneumatic repair services providers that offer services at your doorstep. We offer a wide range of products to maintain any hydraulic system at a low cost. Order online by dropping an email on sales@cmindustrysupply.com or call us at +91 8888851242 or +61 432112288 today.