Posted on 24th Jun 2024

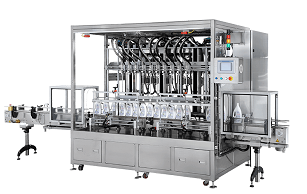

In the realm of manufacturing, efficiency and precision are paramount. One crucial component that enhances both aspects in the operation of filling machines is the Variable Frequency Drive (VFD). These devices play a pivotal role in optimizing performance, improving control, and ensuring cost-effectiveness in the production of various goods, from beverages to pharmaceuticals. Here’s an exploration of how VFDs are transforming filling machines in manufacturing:

Filling machines require precise speed control to maintain accuracy in filling volumes, especially when dealing with different types of containers and products. Variable frequency drive offer adjustable speed settings, allowing manufacturers to fine-tune the operation of pumps, conveyor belts, and other components involved in the filling process. This capability not only ensures consistent filling levels but also minimizes product waste and enhances overall production efficiency.

Traditional filling machines often operate at fixed speeds, consuming more energy than necessary during periods of lower demand. VFDs optimize energy usage by adjusting motor speeds according to real-time production requirements. They achieve this by supplying only the amount of energy needed at any given time, resulting in significant energy savings and reduced operational costs over the long term.

The controlled acceleration and deceleration provided by VFDs contribute to smoother start-up and shutdown processes for filling machines. This capability not only extends the lifespan of mechanical components but also reduces wear and tear on motors and associated equipment. By minimizing abrupt starts and stops, VFDs help maintain equipment reliability and reduce maintenance downtime, thereby maximizing overall equipment effectiveness (OEE).

Manufacturing environments often require flexibility to accommodate varying production demands and product types. VFDs enable filling machine to operate at different speeds and accommodate changes in production schedules without the need for extensive manual adjustments or mechanical modifications. This flexibility enhances operational agility, allowing manufacturers to respond swiftly to market demands and optimize production output.

Consistency in product quality is crucial for manufacturers across industries. VFDs contribute to better process control by ensuring uniform filling speeds and volumes, which directly impacts product quality and customer satisfaction. By minimizing deviations and errors in filling operations, VFD-equipped filling machines uphold stringent quality standards and regulatory compliance, enhancing the reputation of manufacturers in competitive markets.

As industries embrace digital transformation, VFDs play a pivotal role in enabling connectivity and integration within smart manufacturing ecosystems. These devices can be equipped with advanced monitoring and diagnostic capabilities, allowing operators to monitor performance metrics in real-time, predict maintenance needs, and optimize production workflows. Integration with Industry 4.0 technologies enhances overall operational visibility and efficiency, paving the way for predictive maintenance strategies and continuous improvement initiatives.

Darwin Motion Variable Frequency Drives (VFDs) are indispensable tools for optimizing filling machines in manufacturing, offering enhanced speed control, energy efficiency, flexibility, and improved process reliability. As industries strive for greater productivity and sustainability, integrating VFD technology into filling machines not only boosts operational efficiency but also supports cost-effective production and superior product quality. Embracing VFDs represents a strategic investment for manufacturers looking to stay competitive in today’s dynamic market landscape, driving innovation and excellence in filling operations.