Posted on 22nd Dec 2022

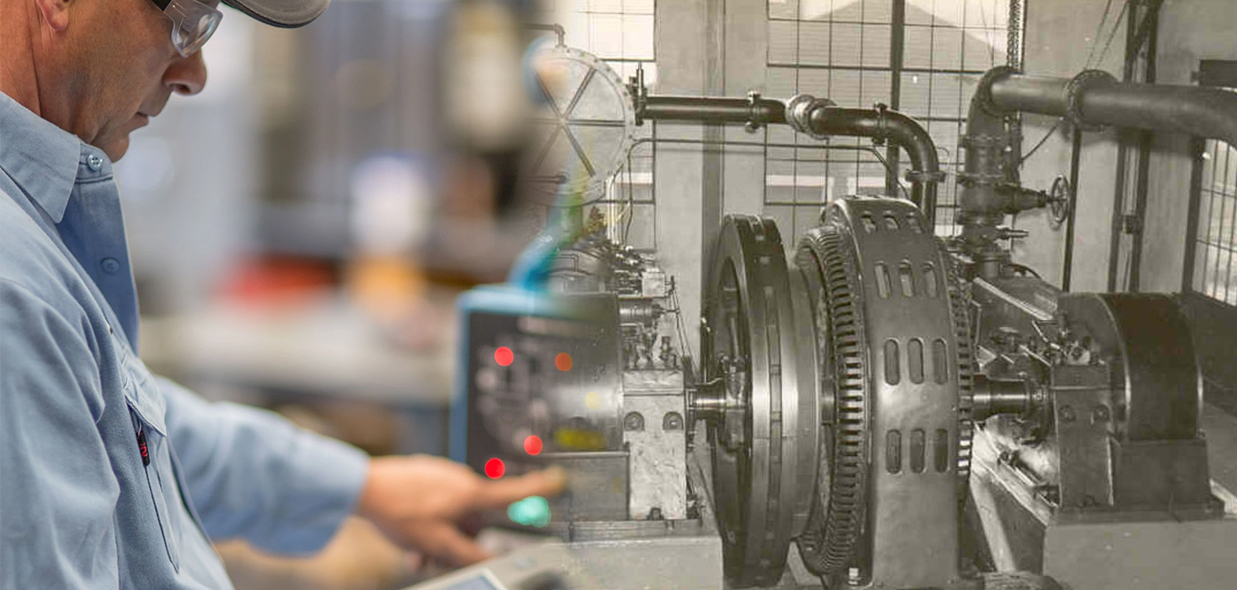

SIGNIFICANCE OF AIR COMPRESSORS

Most of the air compressors in the world operate using standard, 3 faced induction motors. They are typically powered by electricity, natural gas or diesel. The primary goal of an air compressor is to pressurize the intake air for different industrial processes. The capability of a compressor in air pressurizing is measured in pounds per square inch gauge, widely known as PSIG, which is a comparison of barometric pressure and the pressure inside the tank. Barometric pressure is the amount of air pressure that is present in the atmosphere. As of 2020, the overall share of the Industrial Air Compressors Market was valued at around USD 31.21 Billion & it’s expected to increase with a CAGR of nearly 3.9% between 2021 & 2028.

The capacity of an air compressor is defined as the amount of air that can be produced at a specific PSIG. This output capacity is measured in terms of cubic feet/minute, or CFM. Capacity is regarded as one of the most prominent air compressor purchase factors, especially in the case if an individual intends to run multiple tools simultaneously.

When calculating the required CFM, one should consider the pressure level that is needed & especially if the plan is to use the compressed air continuously. For example, the high-pressure tools that always require constant or near-constant airflow need a higher capacity air compressor. For industrial automation machines that regularly use short bursts of air, like a nail gun, a lower capacity is perfectly suitable. The requirement for air compressors with multiple capacities is very high for the industries.

Compressor Tank Size

Most of the compressors contain a tank for storing the pressurized air until it is ready to use it. Large tanks mean that one can go longer without running the compressor motor, but an individual will have plenty of compressed air in hand to power the tools. Because the compressor is running less, an individual may see cost savings reflected in his/her energy bill.

Method of Lubrication

Whenever an air compressor contains some movable parts, these sorts of components require lubrication for the reduction of wear and tear & hence prolong the machine’s life. Lubricated air compressors typically inject an oil-based solution into the compression chamber that gets distributes it to the parts. These air compressors often require an oil filter to keep the residual oil out of the compressed air. For applications & industries that require 100 % oil-free compressed air, there is availability for oil-free compressors.

Rotary Screw

Rotary screw air compressor specifications generally refer to a positive displacement of the compression system powered by two counter-rotating helical screws, also known as rotors. Air is trapped between these two rotors & that trapped air decreases in volume as it moves, thus resulting in compressed air. Rotary screw compressor specifications, on the other hand, include both lubricated & oil-free compressors, which are designed for prolonged use. Although the rotary screw compressors are very much efficient & durable, they require some ongoing preventive maintenance by a trained professional to achieve the best results.

CONCLUSION

Although the air compressors are easy enough to use, still they can be some of the most complex pieces of machinery in the workplace. In the 1920s, Quincy Compressor was dedicated to helping the consumers to stay informed about the products that they choose & crafting machinery along with the air compressors, air dryers & other compressed air equipment that deliver uncompromising performance and reliability