Posted on 21st Dec 2022

The industrial gearbox industries including automotive, agriculture, food and beverages, construction, wind power, and marine are also leading towards normal production.

As we are reaching toward the end of 2021, travel restrictions are ending as the world is starting back to normal in all sectors. The industrial gearbox industries including automotive, agriculture, food and beverages, construction, wind power, and marine are also leading towards normal production.

In this article, CM Industry Supply Automation share the industrial gearbox market trends in the upcoming years.

The COVID-19 Impact on the Industrial Gearbox Market

COVID-19 pandemic will influence the industrial gearbox sector until at least 2024. However, many reports suggest that there will be a rising demand for gearboxes in great-performance applications that will be the main fuel for market growth in the upcoming years.

The new forecasts give new hope to the industry leaders. They are expecting to take advantage of the predictable market surge.

Worldwide Market Leaders By 2023

More than 30% of the industrial gearbox market will be in the Asia Pacific region since 2018. This makes logic since China and Japan are some of the biggest manufacturing hubs in the world. USA and Germany are following the Asia Pacific zones along with regions in Africa and the Middle East.

Even though the Africa and Middle East regions are lower on the list, they must not be underrated. The risk of climate change is encouraging primary, and third-world regions, to look at optional energy sources. Wind power is predicted to rule the industrial gearbox industry by 2024. Also the construction, material handling, and marine manufacturing.

Africa and the Middle east developing countries are continuously focused on investing in the mining, manufacturing, and industrial automation industries. This is good news for the global market treads of industrial gearbox!

The Future of Gearbox modernization

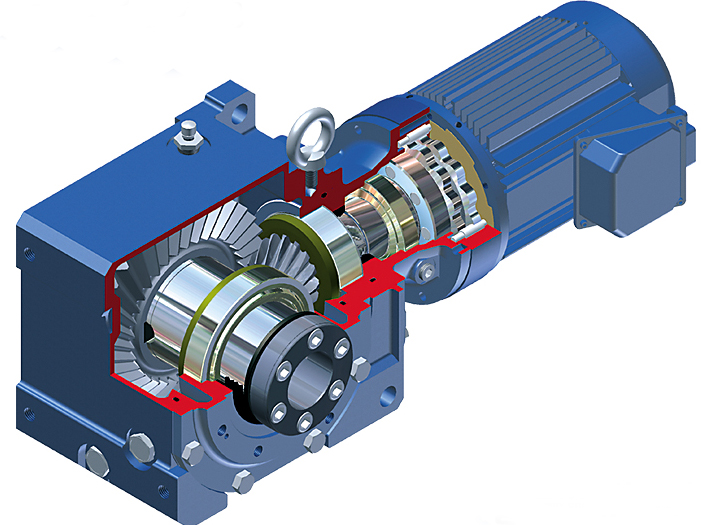

According to CM Industry Supply Automation, global manufacturers are relying mainly on automation for higher quality, quicker, and less expensive production. This gives flexibility to servo manufacturers to make gearboxes, which are smarter and have a larger torque density. There will be the most vital advancement in gearbox design i.e. the change from a parallel shaft profile to an accurate planetary design. This offers load sharing between gears to raise lifespan and torque.

Along with heat treatment procedures, the gearboxes lifespan are increased even further. Heat treatment procedures raise the hardness layer by more than thirty times as compared to optional treatments.

What will be the future?

With predictions and trends showing a positive direction, one fear remains i.e. overuse and weakening of gearboxes and gearbox parts. As manufacturers are pushing machinery harder to meet deadlines and raise production. Logically, industrial gearboxes will undergo wear and tear.

This is why businesses need to perform routine maintenance and make sure that gearboxes attain maximum efficiency and contribute the highest advantage. The team at CM Industry Supply Automation are specialized in industrial gearbox supply and gearbox repair services. You can find the Lenze gearbox, Lenze worm gearbox and more industrial gearboxes range at the most reasonable price.

Along with industrial gearbox range, you can also get Electric Motors, AC Drives, Hydraulics, Sensors, Servo control panel, Servo Drives, HVAC Drives, SCADA Control Panel Touch Panel, HMI, pneumatics, DSC Control Panel, Sensors, VFD control panel, PLC Control panel sales and repair services.